Brake Skimming Testimonials

Read what people who use a Pro-Cut disc skimming machine have to say about it...

Sutherland M Power Cars make savings with Pro-Cut

Sutherland M Power Cars in Winford, Bristol installed the Pro-Cut on-car brake lathe in their workshop a few months ago and have been making savings on their sales car preparation ever since.

David Swinney, Service Manager at Sutherlands, said; “We sell a lot of high performance vehicles but with new brake discs sometimes costing over £300, we were spending a considerable amount of money on sales car preparation. With the Pro-Cut machine we are now able to resurface the discs, bringing them back to ex-factory condition making them as good as new. We are also using the brake lathe on customer’s cars especially those experiencing brake judder, so as well as the savings we make we are able to save our customers money too.”

David had previously used a Pro-Cut brake lathe when he worked at a Porsche dealer, so when he arrived at Sutherland Cars he knew the workshop would benefit from a skimming machine as much of their work is on BMW, Mercedes and Audi vehicles with big costly brake discs.

Sutherland M Power Cars can be found at www.mpowercars.co.uk

911 SBD

911 SBD is an independent Porsche repair specialist in North-West London. The owner Raj Bose bought his first Pro-Cut machine 3 years ago and in 2011 upgraded to the PFM 9.2. 911SBD recommends brake disc skimming in preference to disc replacement (as long as discs are not below minimum thickness) to permanently solve brake vibration problems. You can see his page on this here:

Many motorists have taken their vehicles to 911 SBD as their technicians can skim discs on a wide range of vehicles as well as Porsche, such as BMW, Bentley (all models) VW Touareg and Phaeton, and the Audi RS range.

EBC Brakes

The specialist brake components manufacturer EBC recommends Pro-Cut. See their article which explains brake judder and its solution in more detail at http://ebcbrakes.com/articles/pro-cut-lathe

Some of the key points that EBC make are:

- Problems with brake judder will not be solved by changing discs. If discs are changed when there is brake judder this will provide a temporary solution but vibrations will return after 3,000 to 6,000 miles

- Pro-Cut machines work on both plain discs and even better on slotted and drilled discs of all types.

EBC started using the Pro-Cut lathe 8 years ago after investigating numerous vibration issues on cars and found the product was not to blame but in 95% plus of the cases alignment was the issue.

Spring brings a wave of issues on vibration after potholes and slippery roads causing vehicles to nudge kerbstones mis align wheel hubs.

The weak stance is to throw a new set of rotors at the customer using mythical expressions such as 'Your discs are warped' which is physically impossible with a rigid large mass of cast iron but this stance leads to a problem repeat and eventually reputation damage.

Recommending Pro-Cut solves it all, even on new discs.

If a vehicle comes in for service with brake vibration, installing new parts without a Pro-Cut is a waste of time and materials and Garages can really gain friends and satisfied customers using a Pro-Cut to perfect their brake installations.

It is very telling that a brake disc manufacturer recommends that discs should be skimmed as a solution to brake judder. Along with virtually all vehicle manufacturers (whose engineering departments have tested the Pro-Cut machine), this confirms that brake judder can only be permanently solved by correct machining of the discs directly on the vehicle.

D & B Automotive

Des Johnson of D&B automotive recently upgraded his Pro-Cut PFM 9.0 disc skimming lathe to the latest PFM 9.2 version. Over the last 2 years Des has used his 9.0 regularly but realised he needed a bigger lathe to work on high-spec Audis, BMWs and Bentleys, especially with D&B receiving ever more of enquires via Skim My Discs, the Pro-Cut drivers’ website. Whilst we were on-site installing the new Pro-cut brake lathe, Des commented:

I do a lot of electrical diagnostic work as I have the latest kit for this. Customers with top of the range Audis and BMWs who come to have their discs skimmed then also need diagnostic work which I can provide. So Skim My Discs and the Pro-Cut brake lathe have generated multiple new customers and extra business for my workshop. This has been a really good investment

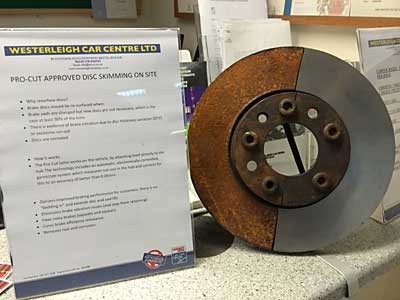

Westerleigh Cars

Neil Skuse of Westerleigh Cars in Bristol likes to be different. He knows that by offering something that other garages can’t he will deliver better service, attract more customers and increase his revenues and profits. That’s why in late 2012 Neil invested in a wheel alignment kit, which paid for itself quickly. And that’s also why Neil invested in a Pro-Cut on-car brake lathe in January 2014.

After 3 months of using his Pro-Cut machine Neil is delighted. He commented: “Our technicians like using it, customers like the results it gives and I’m pleased that it is getting the use that we predicted. In fact one or two customers have even given us positive feedback on our Facebook page”. The picture shows Neil’s counter-top display which attracts a lot of attention.

The Pro-Cut on-car brake lathe skims discs directly on the vehicle. It corrects run-out and eliminates brake vibration, removes rust and ridges and delivers prefect braking for much less than the cost of replacement discs.

J Day Engineering

I recently had my Porsche serviced and they wanted £1100 for front discs and pads fitted. Had front and back skimmed and fitted with Porsche approved pads at J Day Engineering in Henstridge for a fraction of the cost. Service was excellent, the brakes are like new, thoroughly recommend James and the team at J. Day.

The Jag Garage recommends Procut

Central Garage in Snaith, (www.centralgaragesnaith.com) originally established in 1928 and simply known locally as "The Jag Garage", has been around for over 40 years. Passing through three generations of the family, it has evolved into a fully equipped diagnostic garage specialising in Jags and Landrovers. Andrew Hannah and his team at the Jag Garage have a reputation for honesty and pragmatism when repairing vehicles (needed when fixing old jaguars!) and like to provide customers with good old fashioned top quality all round service and great value for money.

When servicing customers brake systems, Andrew found that he was having to replace brake discs that still had plenty of life left in them, but suffered from ‘warped disc syndrome*’. This was costing his customers money and taking up his technicians valuable time. He felt there must be a better option and that’s when he found out about the Pro Cut brake disc skimming system.

Andrew was given a very comprehensive demonstration by the Pro-Cut tech team, and could instantly see the benefits of the machine. Skimming discs on the wheel meant he could cure brake vibration quickly, accurately and permanently. Great news for thrifty customers and, most importantly, time saved in the workshop to get on with other pressing jobs.

Andrew had this to say about his experiences of the ProCut brake lathe:

As a long-standing and experienced ProCut user, I would gladly recommend the brake lathe to a prospective new user. It allows us to offer a really great service to our customers. The machine itself is of excellent quality, easy to set up and easy to use. It has paid for itself three times over already! The technical backup we get from Pro-Cut is also excellent.The ProCut lathe has clearly been a great asset at The Jag Garage with a good return on investment. Everyone who knows Andrew and his team knows he would not offer this service unless he really believed in the results he gets.

Footnote:

* Warped Discs generally refers to discs with Disc Thickness Variation (DVT) caused by disc run-out. This occurs when a disc is not aligned with the wheel hub, and wears unevenly, leading to brake vibration. The discs are not really warped, but it’s a term we often hear used by the motorist in the street. On-wheel brake skimming is the only way to permanently correct this problem. Brake manufacturer EBC recommend all new discs are skimmed when fitted to a vehicle (ebcbrakes.com)